Unlocking the Best SR22 Rates: A Comprehensive Guide

Find the most competitive SR22 insurance rates and get the coverage you need today.

Spray Control Secrets that Pros Don’t Want You to Know

Unlock the hidden spray control secrets that top pros keep under wraps and elevate your skills to the next level!

Mastering Spray Control: Top Techniques for Flawless Application

Mastering spray control is essential for achieving flawless application in various fields, from agriculture to painting. One key technique is to establish the right distance between the spray nozzle and the target surface. Generally, maintaining a distance of 12 to 18 inches allows for optimal coverage and minimizes overspray. Additionally, considering the wind conditions and adjusting your spray angle can significantly enhance accuracy, especially in outdoor applications. Understanding the spray patterns of different nozzles can also contribute to more effective results, ensuring even distribution and reducing waste.

Another important aspect of spray control is the choice of appropriate settings on your equipment. For instance, adjusting the pressure settings according to the viscosity of the liquid being sprayed can lead to better atomization and coverage. Implementing proper technique, such as a consistent speed and steady hand movement, helps in achieving uniform application. Lastly, practicing on sample surfaces before the actual application can provide valuable insights and allow you to fine-tune your technique, ensuring that you achieve the desired results without any unwanted effects.

Counter-Strike is a popular multiplayer tactical first-person shooter game, known for its competitive gameplay and team-based strategies. Players can enhance their gaming experience with various in-game items, such as skins from the Prisma 2 Case, which adds a unique aesthetic to their weapons.

The Science Behind Spray Patterns: What Every Professional Knows

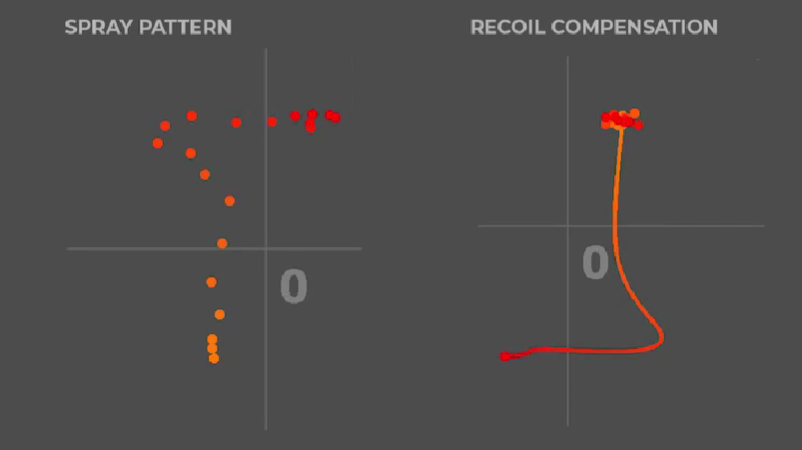

The science behind spray patterns is a crucial topic for professionals in various industries, from agriculture to automotive paint. Understanding how different spray patterns can affect the application process is essential for achieving optimal results. Factors such as nozzle design, pressure, and fluid viscosity play significant roles in determining the pattern's shape and size. For instance, the use of flat fan nozzles can create a wide, even spray, making them ideal for pesticide application, while hollow cone nozzles are better suited for achieving fine mist sprays that cover large areas without over-saturation.

Furthermore, professionals know that spray pattern analysis can significantly impact efficiency and effectiveness. By measuring the application rate and coverage uniformity, users can adjust their techniques to reduce waste and improve outcomes. Common methods for analyzing spray patterns include using water-sensitive paper and conducting pattern tests under varying conditions. Ultimately, a deep understanding of the science behind spray patterns enables professionals to make informed decisions, ensuring that their practices are both sustainable and successful.

Common Mistakes in Spray Control and How to Avoid Them

One of the common mistakes in spray control is improper nozzle selection. Different spray applications require specific nozzle types and sizes to achieve optimal results. Using a nozzle that is too large can lead to overspray and wasted materials, while a nozzle that is too small may result in insufficient coverage. To avoid this mistake, it is crucial to match the nozzle with the particular job. Consider factors such as the type of material being sprayed and the desired application rate. Consulting manufacturer specifications and guidelines can ensure that you are using the best nozzle for your needs.

Another significant error is neglecting to calibrate your spray equipment regularly. Incorrect calibration can lead to inconsistent application rates, affecting both the quality of the job and the longevity of the materials used. To help mitigate this issue, create a calibration schedule that aligns with your usage frequency. This should include checking the pressure, flow rate, and spray pattern periodically. By maintaining your equipment and ensuring it is properly calibrated, you can improve efficiency and reduce wastage, leading to better results in your spray control applications.